AUTOTRANS SYSTEMS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to AUTOTRANS SYSTEMS

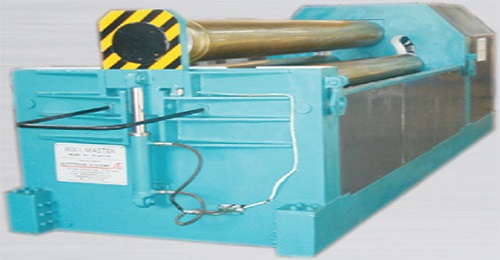

Three Roll Section Bending

The latest in the 3 roll section bending machine design which gives advantage of 4 roll machine ( the bottom roll workind as a pinch roll) which enables clamping of sections at the centre between top and bottom roll to reduce distance between pinch roll and bending roll. Due this working principle of machine the straight portion of section is at minimum which increases effective material utilisation.

Standard Featues

Both the bottom rolls are positively driven by palnatery gear box and hydraulic motor directly mounted in line with roll shaft

The swinging control console gives liberty to operate machine from front or from one side which also makes it possible to remove rolled sections from front without any problem.

All our section bending machine model comes with roller mounted in ball bearing which reduces friction and enhanced torque is available for rotation which other wise will go to waste if plain bush are use which create lot of friction due to metal to metal friction.

All our machine has 2 digital meter to ascertain both the roll position and by maintaining same values one can get repetitively same size of rolling

Optional Features

All 3 rolls positively driven

Electrically operated control console for machine operation from a distance

PLC with HMI for automated component bending/rolling cycle.more than 100 rolling cycles can be saved and recalled at any given time .

Force lubrication system.

Section feeding and locating device

Hold bra

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.